Ready for plant-wide lifecycle improvements?

Reduce critical equipment energy use by assessing system performance.

If your equipment can’t come to us, we’ll come to you. We understand the hassles and wasted time that can accompany emergency repairs and the immediate need for a spare part. And we also understand the considerable time and effort needed for proper on-site installation and maintenance.

From maintenance to management, our highly qualified project managers, engineers and technicians can be on-site to help your operations run smoothly. We achieve this through the following comprehensive evaluation process:

Define: Establish baselines on current equipment and operating performance.

Identify: Determine repairs, upgrades and improvements to enhance equipment performance.

Perform: Repair, upgrade and provide a recommendation to obtain optimum uptime and reliability.

Continuously monitor: Install near real-time monitoring systems to continuously measure system performance on an ongoing basis.

Typical system assessments include:

- Machining and repair welding

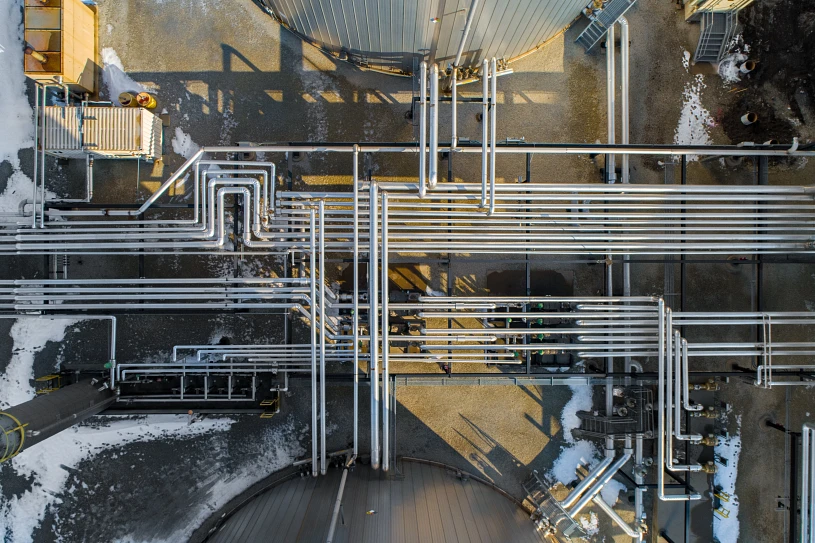

- Piping services

- Mechanical upgrades and retrofits

- Installation and startup

- Push-pull services

- Preventive and scheduled maintenance

- Turnkey maintenance

- Troubleshooting, equipment testing and nondestructive examination

- Supervision and project management

- Scheduled inspections and outage services