Nuclear

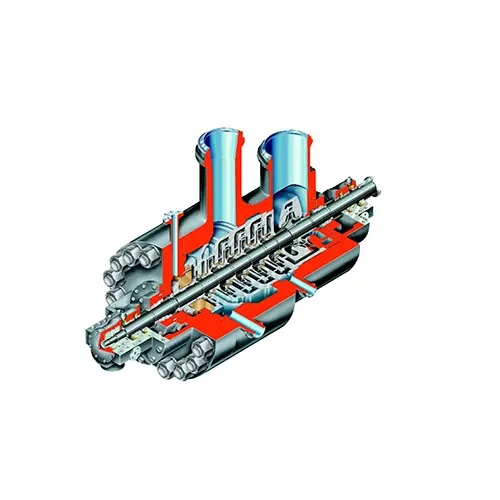

With more than 5,000 pumps and 15,000 valves installed in over 200 nuclear reactors worldwide, it’s obvious that Flowserve is an industry leader in the nuclear space. In fact, we have played a critical role in the development of the nuclear power industry from its birth in the 1950’s, having achieved certified supplier status with several Generation III reactor design firms.

Quality- and safety-certified to build the products your plant needs

Flowserve holds and maintains the necessary qualifications across the globe for the design and manufacture of our pumps, valves and seals, including:

- 10CFR50 App B, 10CFR21, ANSI N-45.2, ASME IX, NBIC-NR, CAN3 Z-299, CSA N285.0

- ISO9001, GS-R-3, NQA-1 and NSQ-100

- ASME Section III Class 1, 2 and 3

- N, NR, NPT stamps, ASME Section VIII ‘U’ stamp

- ASME QME-1

- RCC-M, PED/CE

- JSME accreditation and certification in primary coolant, safety-related and conventional services

- HAF 604, HAF601

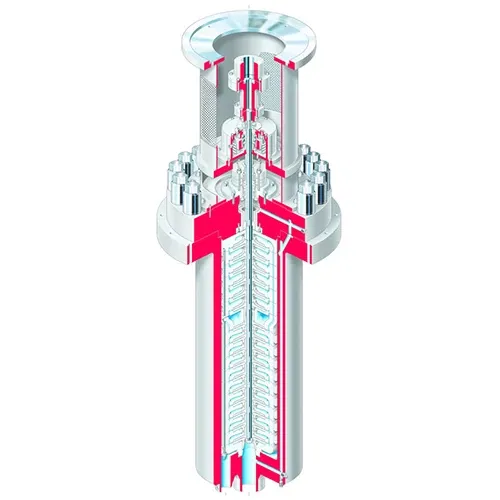

We design and develop our solutions with an eye constantly trained on nuclear safety. Take our N-Seal, the most thoroughly tested and proven primary pump seal in the industry. The PWR N-Seal has regularly achieved MTBR’s (Mean Time Between Repair) of over 125,000 hours, and provides greatly extended coping times under station blackout conditions—meeting post-Fukushima requirements.

Minimizing scheduled outage downtime with on-time delivery and service

We understand that rapid, qualified servicing is essential to station profitability. That’s why we provide on-time delivery of turnkey services and strict adherence to a plant’s schedule. Our engineers are equipped to run the job at the plant, repairing or replacing equipment.

A quick response to non-scheduled outages

Our quality products reduce the frequency of outages. But when they do occur, our global network of QRCs provides a quick response to solve the problem, reducing downtime in the bargain.

Related Products

Let’s discuss your needs

Contact Us