Specialty (Fine & Consumer)

Flowserve customers extend across a variety of processes, consumer products and materials—all of which create unique and complex challenges. Our global solutions and support teams meet the demand for maximum performance, efficiency and reliability.

Flowserve improves your life cycle

The market changes, energy costs fluctuate, and environmental factors continue to evolve. This creates new challenges for you every day. Flowserve helps your team to identify emerging issues and develop solutions that are energy-efficient, safe, and effective.

Flowserve services and repairs ensure your success

Maintaining your installation, start-up and sustainable schedules is vital to ensuring your plant produces as expected and stays on budget. Flowserve is positioned around the world to meet your product needs with the utmost dependability. Our local engineering & technology teams are on the ground or on-call to assist with a wide variety of services whenever and wherever you need them.

Flowserve provides quality, reliability and minimal life-cycle costs

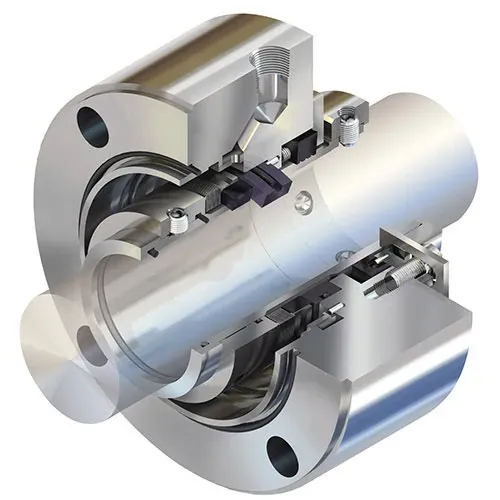

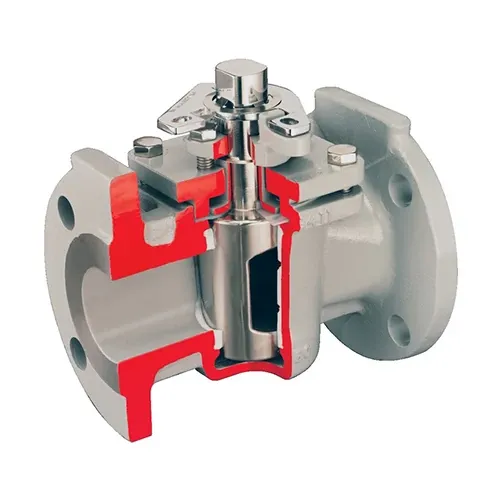

Flowserve legacy chemical process pumps from product brands such as Durco, Durametallic, Byron Jackson and Valtek, are renowned for their reliability. They are used extensively and installed globally for virtually every chemical service due to their extraordinary combination of materials and features. These products have all been designed with safety and environmental concerns in mind, and adhere to both domestic and international standards.

Achieving World-Leading Load Lock Performance

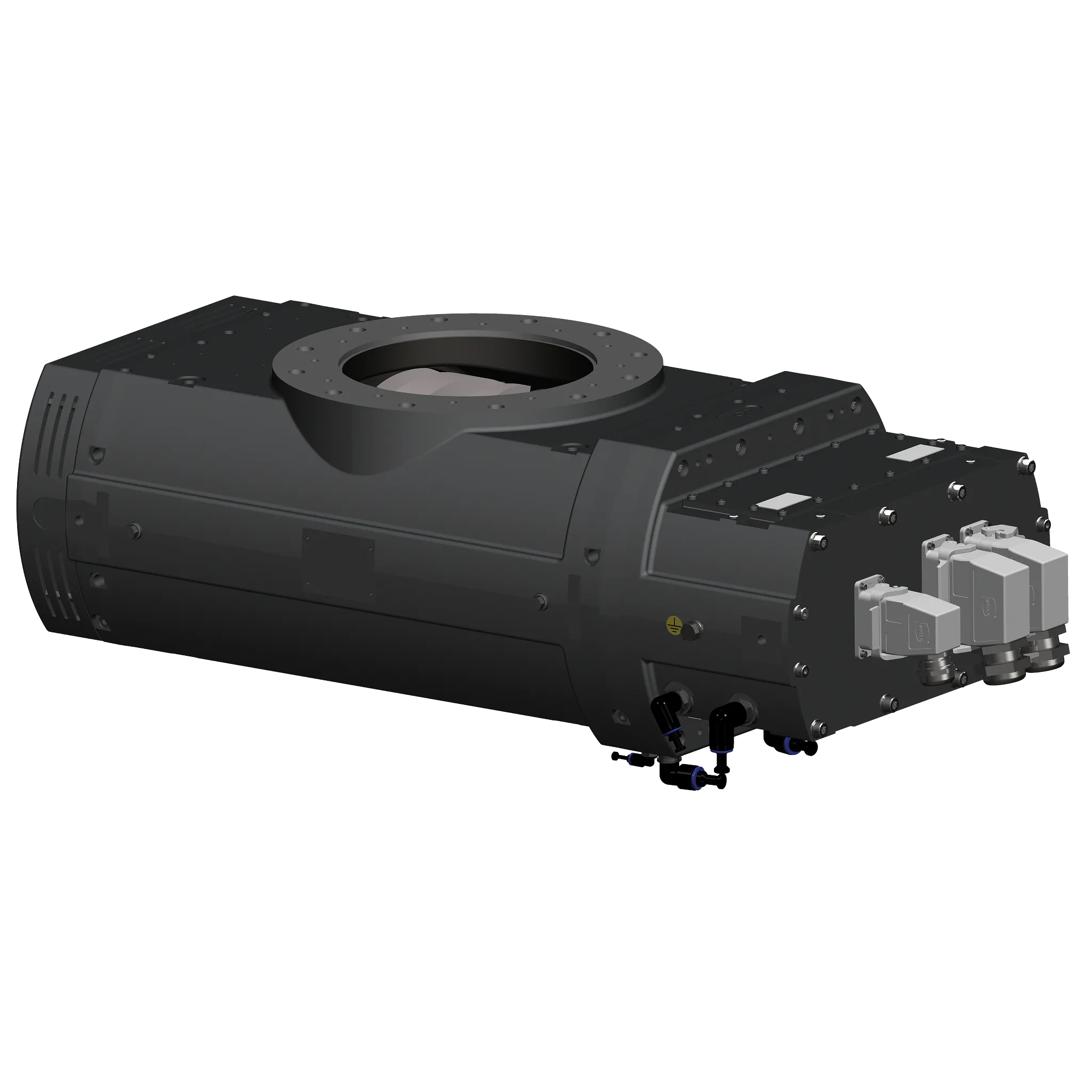

Replacing Roots-type blower systems with SIHI® Boost UltraPLUS dry-running vacuum pumps from Flowserve can enable existing production equipment to achieve the industry’s fastest load lock cycle times to date, resulting in increased throughput and profitability.

Thin Film Production Application Solutions Guide

A valuable reference for anyone associated with the manufacturing of thin film. This guide, written by our thin film manufacturing experts, details which Flowserve products may be best-suited for providing flow control solutions to each plant application.

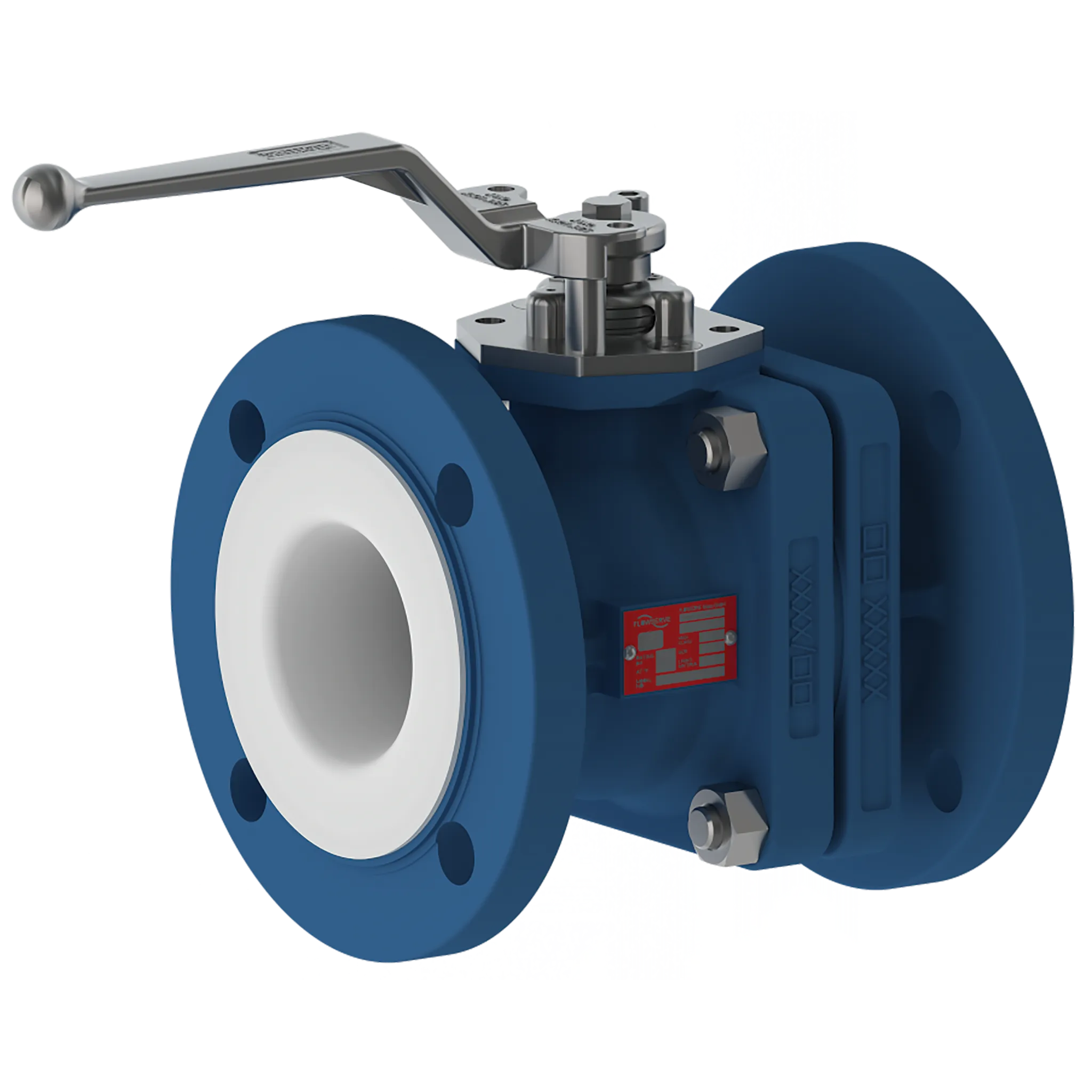

Atomac® AtoStar™ Lined Valves Support the Drive to Digitization

Semiconductor manufacturing requires a level of quality control that’s unmatched in other process industries. That’s why successful companies count on Atomac AtoStar lined valves from Flowserve to control the flow of chemicals used to clean and etch semiconductor components.

Use Cases

For the production of consumer products such asdetergents, fragrances, and soaps, you need a portfolio of equipment that can keep up with demand. The variety of Flowserve solutions enables you to stay nimble and exceed expectations.

Ag chem technology is changing rapidly with population growth and increasing demands on crop protection. Additional growth in business and housing development has put additional demands on end user products such as inks, paints and adhesives.

Flowserve, through our global presence and capabilities, is a one-stop supplier of process equipment needed in the thin film industry. We provide an array of products and services ranging from pumps and precision mechanical seals to control and manual valves. A product for every critical service designed by our specialists ensures low-cost, high-efficiency solutions. Our aftermarket group maintains, services and upgrades equipment to meet your operating goals throughput.

Related Products

Let’s discuss your needs

Contact Us