Energy is the biggest cost driver in any seawater reverse osmosis (SWRO) desalination process. The Flowserve FLEX™ pressure exchanger, an isobaric energy recovery device, is the most efficient device of its type. Capable of recovering more than 98% of hydraulic energy, it drives down the cost of desalination by substantially reducing operating costs and capital expenditures.

... Read more Read less- Best-in-class hydraulic efficiency - The Flowserve FLEX pressure exchanger recovers more than 98% of the hydraulic energy of the brine stream, substantially reducing overall plant operating costs. It also enables high-pressure pump capacity to be reduced by as much as 60%, leading to significant capital savings.

- Simple design - With only four major internal parts, the simple design of the FLEX energy recovery device ensures high reliability and uptime with low operating and maintenance costs. A sight glass allows for easy visual inspection and manual speed measurements.

- Extremely low mixing rate - Mixing is a key performance indicator for isobaric devices. The Flowserve FLEX energy recovery device has an extremely low mixing rate, resulting in lower membrane feed salinity. The upside is lower high-pressure pump and ERD booster pump power consumption.

- Minimal lubrication - The axle-guided rotor design significantly reduces lubrication flow requirements compared to other pressure exchangers, contributing to the unit’s industry- leading efficiency

- Highest capacity per unit - The FLEX boasts the highest unit capacity of any pressure exchanger. Fewer units are needed to achieve the total flow capacity of the plant and the plant footprint can be smaller.

- Smallest footprint - Smaller and less complicated headers along with fewer couplings help to simplify installation and keep associated costs low.

- Lightest design - The Flowserve FLEX is the most compact and lightweight pressure exchanger available.

- Easy to retrofit existing installations - The Flowserve FLEX a simple drop-in replacement for existing isobaric energy recovery devices.

Operating Parameters

- Flows: up to 135 m3/h (600 gpm)

- Temperaures: up to 50ºC (120ºF)

- Pressures: up to 83 bar (1200 psi)

Size Range: 150 and 200 mm (6 and 8 in.)

Materials: Titanium and Ceramic

Simple and reliable operation — continuously

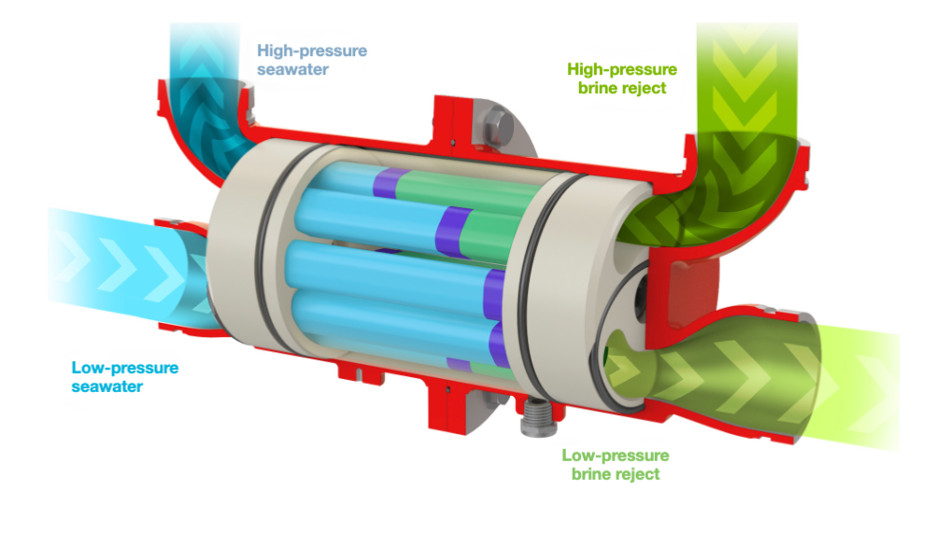

Hydraulic energy from the high-pressure brine reject stream is transferred by the Flowserve FLEX pressure exchanger to the seawater membrane feed.

Low-pressure seawater flows into the FLEX energy recovery device, filling a duct within the rotor and causing it to rotate. (No external drive is needed.) Simultaneously, high-pressure brine reject from the membranes enters the same duct from the opposite side. As the ceramic rotor spins, the low-pressure seawater is exposed momentarily to the high-pressure brine reject stream, at which point hydraulic energy is transferred from the brine to the seawater.

As the rotor continues to spin, the now high-pressure seawater and low-pressure brine reject are discharged out of their respective sides. This process repeats itself up to 900 rotations per minute — 24 hours a day, seven days a week, 365 days a year.