Pulp & Paper

In pulp and paper production, Flowserve solutions are there for every step of the process.

Flowserve is a single resource for all pulp & paper needs

The product portfolio at Flowserve was built with a wide variety of configurations to support the varying needs of our customers. These needs go beyond the production requirements and involve environmental and safety standards as well. We understand the regulations you face and have engineered solutions to keep you from any environmental infractions that might come your way.

High quality is standard at Flowserve

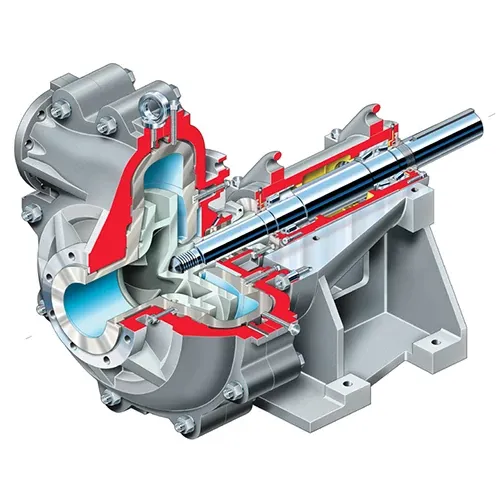

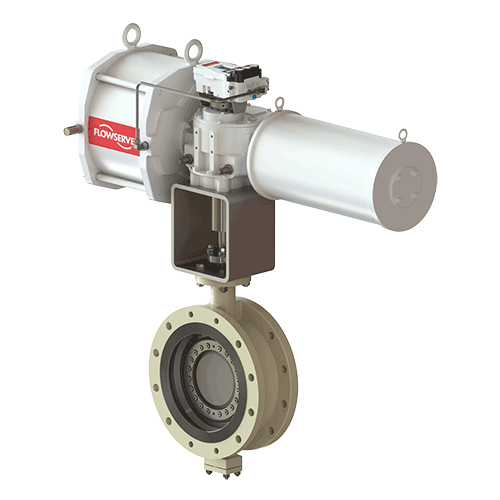

Flowserve equipment is compatible with high alloy materials of construction and suitable elastomers and is engineered to help you increase uptime by working continuously with corrosive fluids and erosive solids at high pressures and temperatures. We’re unique among manufacturers in that we supply and support control, on/off and manual valves in addition to a full range of pumps, automation and boiler house equipment. In fact, the very first NAF valves were developed in collaboration with pulp and paper customers in 1899.

Maximizing efficiency is a continuous goal

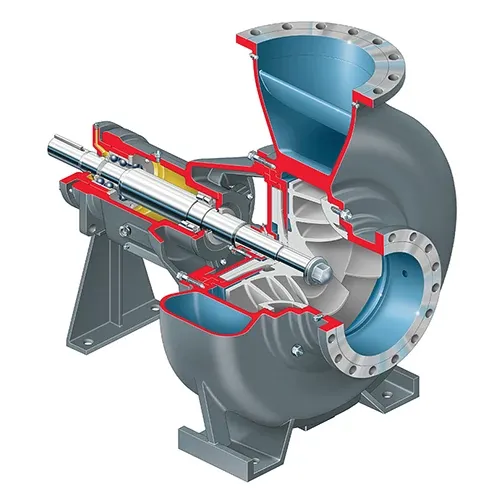

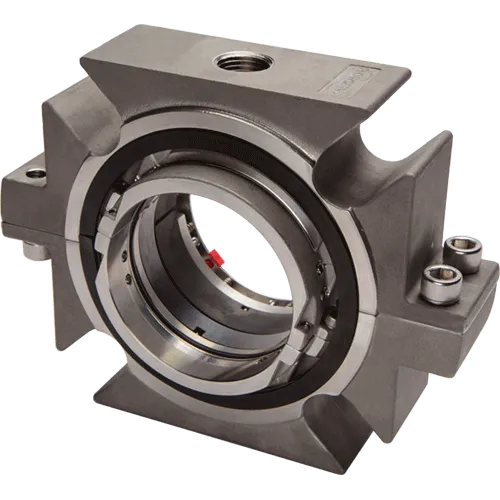

It’s a fact that pulp mills utilizing Flowserve products operate more efficiently by conserving more energy. That’s because our seals are designed to provide an efficient conservation of water, even in those applications plagued by dewatering. Our pumps ensure a continuous process flow with a steady stream that ensures paper continuity.

Equally important is our commitment to technological innovation. Flowserve’s PMV D3 Positioner with Wireless Communication represents a breakthrough in communications technology, improving operational efficiency by allowing communication to, and monitoring of, process control / sensor equipment wherever it is sited. Combined with our ValveSight advanced predictive plant diagnostics system, this technology enables you to make informed decisions on how to operate more efficiently.

Use Cases

The paper machine requires high pressures to fully separate water from the paper. Flowserve solutions do the trick with a properly designed pump impeller to smooth out the consistency of the paper on the wire. The well-metered flow of Flowserve valves has proven them worthy of the paper machine’s critical applications.

Flowserve offers a comprehensive line of flow control products suitable for the most stringent applications in power generation within the mill power house. This includes liquor processing, boiler feed circuits, circulating water, and condensate cooling water.

The chemicals used to brighten and bleach pulp require pumps, seals and valves that can withstand the corrosive nature of the process. Flowserve offers solutions in a multitude of materials to suit the application.

Flowserve engineers are specialized in ensuring high efficiencies when pumping paper stock and maintaining thickness. We pair our expertise with reliable pumps ideally designed for this purpose, such as our FRBH stock pump. The proper mechanical seal will ensure water conservation and limit the amount of excess water added to the process while Flowserve valves provide optimum control of the process.

Related Products

Let’s discuss your needs

Contact Us