Steel & Primary Metals

Steel Mill applications can be tough and hazardous. Flowserve can provide the products and support to keep your plant running strong and minimize your safety and maintenance concerns.

The Flowserve product portfolio ensures maximum compatibility

You need to know, regardless of what and how much you’re pumping, and if there are solids involved, that the pumping systems you’re deploying present no compatibility issues with the chemicals you’re moving. With the industry’s most complete flow control portfolio, Flowserve has a pump compatible with your specific needs. Guaranteed.

With Flowserve, safety is first and foremost

Moving chemicals in the Steel Mill is dangerous work. That’s why Flowserve seals are engineered to prevent leaks that could cause safety hazards. In fact, we have some of the best safety ratings in the industry.

More uptime gives you more focus time on the day-to-day

If you’re concerned about low maintenance and maximum uptime (of course, you are), be assured that Flowserve pumps are engineered for easy set up and exceptionally long life. And when they do need service, our global network of local QRCs can provide fast maintenance for minimized downtime.

Benefits of Design to Value

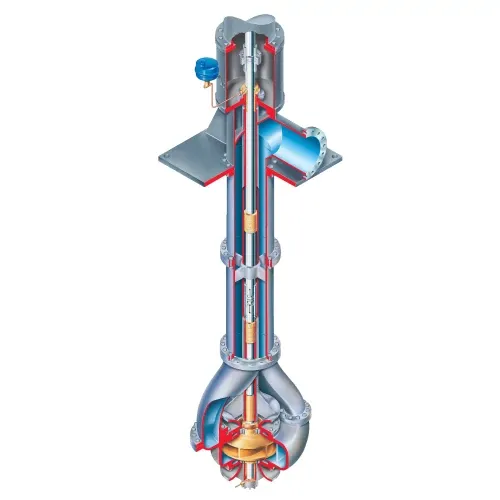

Steel and metal applications are tough and hazardous. You need reliable pumps to keep your plant running strong and minimize your safety and maintenance concerns. See how the newly redesigned Flowserve vertical turbine pump delivers performance, reliability and design flexibility.

Use Cases

Cool water is an important resource needed in the steel mill. High quality seals and other Flowserve products prevent leakage and ensure safety and consistent operations.

Removing water from process in steel mills is tough on equipment. Flowserve has the correct fluid handling components for this process, ones that can extend mean time between maintenance times.

Strong acids remove impurities on metal surfaces within the plant. Flowserve provides customers with the right flows and pressures for operating efficiencies, and ensures reliability.

This application is critical in the steel mills, Flowserve has pumps to handle the often solids-infused water from the quench process.

An inherent necessity is fluid handling in the scale pits. Containing abrasive solids, this application requires the most stalwart pumps, seals and valves for the process. Flowserve can meet this need.

As a part of flue gas maintenance, process pumps and mixers are sealed with Flowserve seals to reduce SOX from plant emissions. Our innovative designs are engineered for limited leakage and easy installation to reduce mean time between failures.

Extracting metals from ores is a demanding process requiring high alloy materials of construction in each process train component. Flowserve can engineer the correct solution for this demanding application.

In line with the high demands of leaching processes, the reclamation of the used acids within the mills is a critical application that can be met by the Flowserve team.

Related Products

Let’s discuss your needs

Contact Us