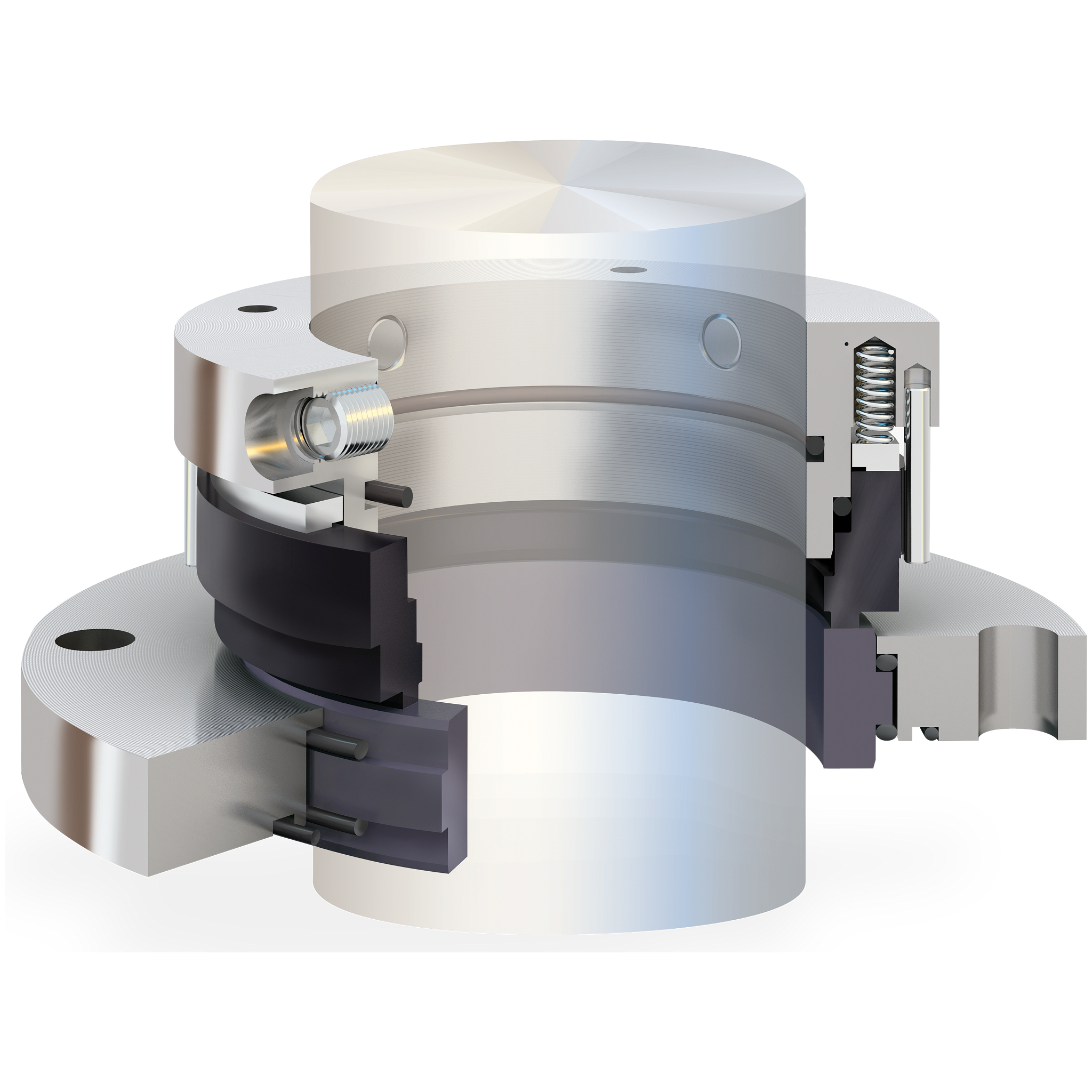

- Self-lubricating carbon or filled PTFE seal face runs completely dry without cooling. Long life and reliability are achieved in the dry vapor space at the top of the mixer vessel while eliminating product contamination from liquid barrier fluids.

- Flexible rotor design compensates for shaft misalignment. Clearances, drive design, seal face dimensions, and o-ring configuration were optimized for the high run-out requirements of mixers and similar equipment. The VRA operates at eccentric run-out levels up to 3.81 mm (0.150 inch) TIR.

- Double o-ring mounted stator prevents distortion. Various configurations are available to fit different equipment types.

- Non-metallic collar option provides superior chemical resistance. Designated the VRA-C, a two-piece collar design eliminates the need for expensive exotic metal alloys in non-wetted areas.

- Optional sanitary gland allows steam cleaning and sterilizing of the seals interior while mounted on the equipment. Sanitary porting aids in the removal of steam cleaning debris.

Size Range: 25 to 178 mm (1.000 to 7.000 in)

Metal Components: 316 Stainless Steel, Filled PTFE

Rotating Face: Carbon, Filled PTFE

Stationary Face: Durachrome, Tungsten Carbide, Aluminum Oxide

Gaskets: Fluroelastomer, Perfluroelastomer, EPR

Springs: Alloy C-276

Operating Parameters

- Pressure: Full vacuum to 13.8 bar (200 psi)

- Temperature: Up to 149C (300F)

- Speed: Up to 350 rpm

VRA with Sanitary Gland

VRA-C with two-piece drive collar